Custom tube bender eliminates cut-off waste of tubular parts for exercise machines

Unison has won an order for a custom-designed tube bending machine and special tooling from Cybex International. Incorporating a unique servo-driven wiper die mount, the machine has been specifically designed to enable Cybex to reduce waste material costs by eliminating the need to cut shorter tubular parts to length after bending.

Cybex produces a diverse array of physical exercise machines at two large state-of-the-art manufacturing facilities in Medway, Massachusetts and Owatonna, Minnesota. Its unique machines are developed with the help of exercise science principles to be biomechanically correct and generate optimum results with minimum stress on the body.

Nearly all Cybex exercise equipment is based on high quality tubular steel framework, most of which is produced at the Owatonna plant. The framework is a highly visible part of the brand image and therefore needs to combine an aesthetic look and feel with structural strength. To achieve this, Cybex constructs frames from three different sizes of robust 11 gauge steel tubing, using a variety of proprietary tube profiles including flat-sided oval and compressed octagonal shapes. Producing smooth, wrinkle-free bends in these types of tubular profile is technically challenging and demands considerable expertise.

Cybex currently uses hydraulic tube benders to handle the bulk of its production needs, together with a single all-electric CNC machine for more complex parts that require multiple bends with different radii. The tube parts range in length from 2 to 10 feet and involve a diversity of bends – from shallow curves to tight bends with a centreline radius as small as 4.8 inches. Most parts require bend accuracies of plus/minus 1 degree or better, to help achieve end-to-end positional tolerances as tight as 0.03 inches. After bending, the parts are welded, cleaned, shot blasted and powder coated. To ensure that the final product is unblemished, every stage of this process is subject to stringent quality control.

Parts with complex bend shapes are produced in small batch sizes – typically of between 12 and 30 – on the company's existing CNC bending machine. Like most rotary draw tube benders, this is fitted with a stationary wiper die to help control material flow and prevent tube collapse during tight radius bending. The permanent presence of the die imposes a limit on the minimum length of tube that can be bent. This means that to produce short parts, Cybex has to use overly long tubes and then cut them to length after bending. This has several drawbacks: it is time-consuming – it is much more difficult to cut a formed part than a straight tube – and demands additional processing and quality control stages. It also creates material scrap, which is expensive and at odds with the company’s commitment to environmentally responsible manufacturing practices.

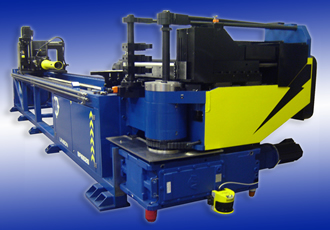

The custom bending machine that Unison has designed will bend these complex and short tube shapes without generating cut-off waste. Instead of a stationary wiper die, Unison's machine uses a unique swing-away tool mount which – like all motorized axes on the machine – is driven by a software-controlled servomotor. Moving the wiper die away from the pressure die towards the end of the bend cycle allows the tube feed mechanism to be driven closer to the rotary bending head, facilitating fully automated production of short parts.

The new machine is based on a 4-inch (100 mm) all-electric CNC tube bender from Unison’s Breeze range. It has also been configured with multi-radius bending capability and multi-stack tooling to allow complex parts to be produced in a single, uninterrupted machine cycle. The precision of the new machine is also aided by the inclusion of a unique laser-based system that automatically measures and adjusts bend angles to compensate for tube spring-back after bending.

Cybex cites fast and repeatable software-controlled set-up, bend accuracy and low power consumption as key reasons for its choice of a Unison tube bender. Other factors include very favourable comments from machine operators at reference companies that Cybex visited during its pre-order selection process, and Unison’s willingness to develop a custom tube bending machine specifically to help improve the flexibility and efficiency of manufacturing small parts.

As Jim Saynor, Unison’s Senior Commercial Manager, explains, “Most of our machines are used for bending tubes with round profiles. The Cybex application is unusual, involving a diversity of tube profiles, and the company has built up considerable expertise in this highly specialist discipline. We have worked closely with Cybex and our tool manufacturer to ensure that the machine we deliver will provide a right-first-time manufacturing solution, from the moment that it is installed. This collaboration included videoing existing bending operations to make sure that every iota of Cybex's specialist know-how is encapsulated in the design of the tools, machine and tube bending methodologies.”

Similar articles

More from Unison Ltd

- Precision tube bending takes next step in evolution 1st March 2016

- Bend that tube exactly the way you want it 19th January 2016

- Powerful all-electric pipe bending machine swings into action 1st December 2015

- Custom all-electric tube bender will accelerate right-first-time production for precision metal fabricator 21st September 2015

ed.jpg)

Write a comment

No comments