Industrial gear units and driving data in the cloud all at Hannover

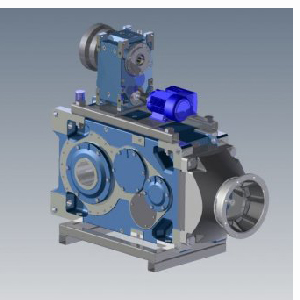

Now providing extruder flanges optimised for heavy duty operation, NORD DRIVESYSTEMS has added an all new-supplement to its modular industrial gear range. Several different extrusion flanges are available for each of the industrial gear units from size 5-11, with rated torques from 15-80kNm. Almost all usual dimensions can be adapted. Extra-large thrust bearings ensure that all process forces are absorbed and provide enhanced durability for long lifespans.

This new option for the industrial gears enables primary and secondary plastics and rubber manufacturers and their suppliers to create safe and highly reliable drives in very customisable configurations.

The NORD industrial gear range offers a variety of input and output shafts and gaskets, flexible mounting directions, and thermal monitoring solutions. The extruder flange as well as industrial gear units in two additional sizes will be showcased for the first time at the 2017 HANNOVER MESSE exhibition.

The NORD industrial gear range offers a variety of input and output shafts and gaskets, flexible mounting directions, and thermal monitoring solutions. The extruder flange as well as industrial gear units in two additional sizes will be showcased for the first time at the 2017 HANNOVER MESSE exhibition.

NORD DRIVESYSTEMS will be showcasing its extruder flanges in Hannover, 24th-28th April as well as its new cloud solution for remote drive monitoring and analysis.

For IoT-driven machine and plant engineering, NORD DRIVESYSTEMS are also offering solutions for making drive data available in real time in a cloud environment.

All drive axes can be monitored from anywhere in the world via an Internet connection. The concept was first deployed in the application test centre at the German NORD headquarters, where it has been thoroughly tested and has proven its reliability in a drive network utilising standard interfaces and components.

AC vector drives and motor starters controlled via Profinet simultaneously transmit live status data in UDP packets, on the same bus line, without affecting regular control communication.

The cloud-enabled drives send data about their power consumption, speed, and voltage, as well as the status word. Tunnelled through a Siemens PLC, all of this information is transmitted to an IoT gateway and on into the cloud.

Status data can then be analysed for energy profiling, asset management, and remote maintenance purposes. Of course, any overload and error states can be visualised. The drives can also transmit additional application data into the cloud at any time - for instance, data of connected sensors and actuators.

Moreover, other parameters can be derived from available status data, notably current oil temperatures. NORD has successfully validated this in initial tests. Such data allows for conclusions about lubricant aging that can be used for predictive maintenance.

NORD continues to work on and further refine IoT-related and Smart Factory concepts. Novel NORD drive solutions that have already been available for some time include economic condition monitoring implementations based on virtual sensors.

These applications will be presented at HANNOVER MESSE, as well as the product innovations in hall 15, at stand H31.

Similar articles

More from Nord Drivesystems/Nord Gear

- Extruder-type drives for plastics industry 28th January 2020

- Condition monitoring for predictive maintenance concepts 6th January 2020

- Cost reduction through efficient energy-saving motors 11th December 2019

- New products from NORD at SPS 18th November 2019

Write a comment

No comments