Controls are at the hub of networked production

As part of the Industry 4.0 area at EMO 2017, HEIDENHAIN is presenting its Connected Machining system of production in which all work steps are networked - from the design to the deliverable component – via the company’s TNC control. It can access all order related information in a company network, enabling efficient exchange of data. Partner companies in the areas of CAD/CAM, machine tools, tool measurement and tool management will collaborate in the demonstration.

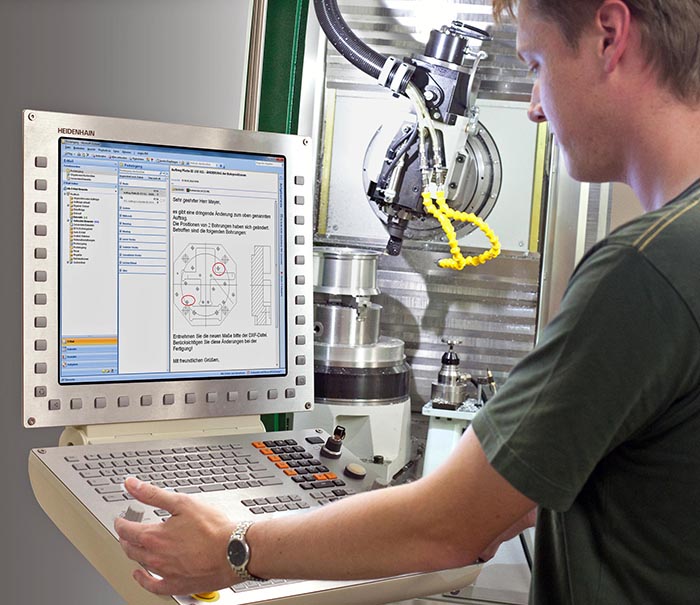

HEIDENHAIN’s premise is that a workpiece is produced on a machine tool, so all information should be consolidated there and data on the status and quality of a workpiece must flow back into the production IT system. The machinist, who is responsible for the quality of components and for staying on schedule, needs to have access to all this data.

In the scenario to be presented, calibrated tools are already in the machine magazine, the operator having scanned a code on each tool holder when loading it, so the TNC 640 knows which cutters are available. Using the control’s Remote Desktop Manager software, the CAM system can be accessed directly, while for its part, the CAM software interrogates the tool database during program creation.

In Batch Process Manager, the operator schedules execution of the production job on the machine. NC programs and the position of the clamped workpiece on the pallet are linked with respect to the order and sorted into a list according to priority. The TNC operator is able to schedule several production orders simultaneously.

The control supports this by comparing the tools required to run the program with the cutters actually available in the machine, reporting any tools that are missing. The operator can then, for example, output a list of new tools that need to be prepared to execute the job. Information on the estimated machining time can be used for further order planning and, together with information from the tool management system, for ordering new tools.

New StateMonitor software supports the operator, capturing data from connected machines, presenting a real-time view of machine status and sending messages to computers throughout the company as well as to mobile devices. The software can send a message to the tool presetting station if the life of a tool is approaching a critical value. Based on stored data, new tools can be preset, a unique code added to the holder for unambiguous identification and the data sent back into the network so the CAM system and virtual machining software are able to access it.

Automatic workpiece measurement on the machine delivers important data for quality assurance, which can be archived or evaluated. The data is centrally available to all other systems, meaning that from the NC program to the tool presetting station, all links in the process chain can be optimised.

Core components of HEIDENHAIN’s Connected Machining are the company’s DNC interface, the Remote Desktop Manager and the StateMonitor software. The interface establishes a connection to enterprise resource planning systems and production control systems and links StateMonitor to the company network. Remote Desktop Manager provides access to all Windows applications.

Furthermore, functions for data presentation such as viewers for PDFs and graphics files as well as for CAD files in STEP or IGES format are a standard feature of TNC controls from HEIDENHAIN. A browser is installed in the control, enabling simple Ethernet connection to a company network.

Similar articles

More from HEIDENHAIN (GB) Ltd

- Manual 2D inspection becomes faster and more accurate 8th August 2018

- Heidenhain controls allow access to order processing data 12th February 2018

- New touch screen controls on show at MACH 2018 8th February 2018

- Industry 4.0 compatibility of controls at Southern Manufacturing 13th November 2017

Write a comment

No comments