Linear drive solutions offer independent and precise sub-systems

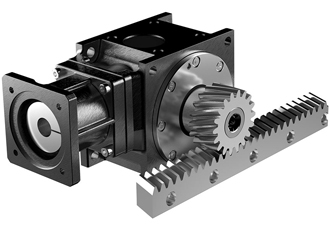

Provider of power transmission solutions, Drive Lines Technologies, now offers a complete linear drive solution incorporating rack and pinion mechanisms that complement the MS-Graessner ranges of precision servo gearboxes, including KS-TwinGear, DynaGear, DynaGear DG and DynaGear PL systems. These solutions include low-backlash precision gearboxes, shrink-fit direct shaft mounted pinion gears and precision toothed racks with dedicated lubrication systems.

They offer independent, precise sub-systems that can be easily mated to a wide range of Servo motors and installed and maintained on many automation systems.

The racks’ drives are available in a number of precision classes and can be supplied to suit individual applications. The teeth can be cut straight or helical; have milled or ground flanks; and are hardened for durability. A range of pitch error tolerances combined with the Graessner gearboxes backlash options enables them to offer Professional, Ultimate and Ultimate Plus precision grades.

The DynaGear System range is designed to be smart, light and accurate. It is available in eight sizes from 53-2,160Nm and can generate feed forces up to 35kN. Gear ratios range from 3:1 to 100:1 and with input motor speeds up to 8,000rpm, output speeds up to 10m/s can be achieved. To meet the needs of a wide range of applications, it is available in three precision classes and gear module sizes 2 to 6.

DynaGear DG Ecosystem, is a highly efficient and economical solution. Available in a smaller range of sizes 53-390Nm, maximum feed force is 11kN and top speed is 6m/s. Gear ratios from 5:1 to 15:1 are available and there is a choice of 2 precision levels, module sizes two to four.

DynaGear PL Ecosystem is a compact, efficient and economical solution. Its smaller sizes range from 53-210Nm; feed force is up to 8kN and output speed can reach 6m/s. Similar to the DG, gear ratios are from 5:1 to 15:1 with two precision classes and Mmodule size two to four.

KS TwinGear System units are designed to be compact, highly powerful and accurate. They are available in eight sizes from 225-1,1250Nm and can produce feed forces up to 200kN. 8,000rpm motor input speeds allow output speeds of up to 4m/s and transmission ratios up to 75:1. Larger gear modules are available to suit from two to eight.

All rack and pinion systems supplied by Drive Lines can be fitted with an integral, automatic lubrication system that can be tailored to individual requirements.

Linear guidance, couplings and other components can also be selected to complement the Gear System solution to offer a package of parts for any precision and dynamic automated linear axis

Downloads

Similar articles

More from Drive Lines Technologies Ltd

- Linear drive solutions offer independent and precise sub-systems 11th October 2017

- High performance bevel gearbox range extended with new size 18th September 2017

- Mechanical Backlash: How much is too much? 5th September 2017

- Performance and longevity improved through dynamic balance 7th August 2017

Write a comment

No comments