How does a Linear Induction Motor (LIM) work?

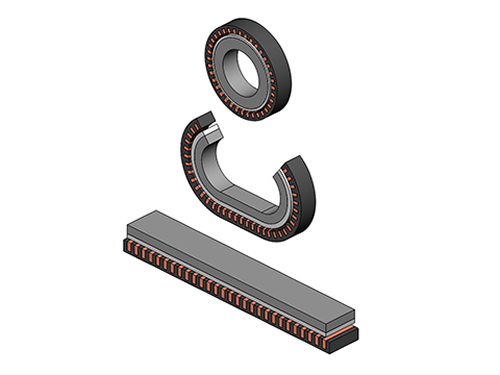

Let’s break this down and make it simple, Linear induction motor (LIM) theory is most easily understood as a rotary motor that has been cut and unrolled to generate linear motion, instead of rotary motion. It is comprised of two parts, the primary and secondary, which interact with one another only when power is applied. Either the primary or the secondary can be fixed while the other moves.

When three-phase AC power is applied to the primary, a travelling electromagnetic flux wave is induced and moves relative to the primary. The wave induces an electric current in the conductive reaction plate. The induced electric current interacts with the magnetic flux to produce a linear force. The speed of the motor can be varied by changing the input frequency using an adjustable frequency drive.

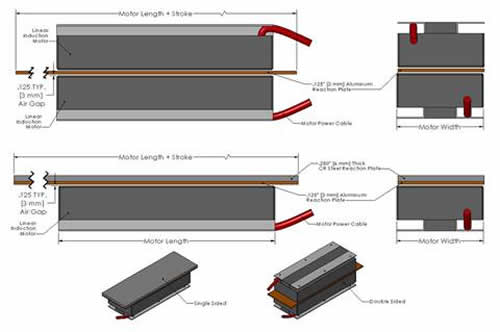

The primary consists of a three-phase coil assembly, equivalent to the stator of a rotary motor. The three-phase coils are wound and inserted into a steel lamination stack along with thermal protection components. The coil windings and stack are then encapsulated in a thermally conductive epoxy.

The secondary, known as a rotor in a traditional rotary induction motor, is a reaction plate. This plate can be comprised of aluminium or copper, and a steel backing. The reaction plate length is equal to the length of the coil plus the stroke. A bearing system is required to maintain the air gap between the primary and secondary.

Linear induction motors can be manufactured in a wide range of force outputs, speeds, and footprints. For single-sided assemblies, the reaction plate consists of 0.125" thick aluminium backed by a 0.25" thick steel plate, and for double-sided assemblies the reaction plate is 0.125” thick aluminium or copper only. If the reaction plate is round and it has a centre shaft with rotary bearings, the system will produce rotary motion.

Why use a Linear Induction Motor?

Linear induction motors are suitable for applications that require rapid movement of large payloads. Linear induction motors can achieve speeds in excess of 1800” per second (45 m/s) and accelerations in the range of 3-4g. Standard LIMs can produce forces in the range of 720lbs (3200N) at a 3% duty cycle. Multiple motors can be used in conjunction with each other to generate larger forces.

LIMs can be found in theme park rides, water rides, people moving systems, high speed transportation and maglev propulsion applications.

Similar articles

More from H2W Technologies

- High torque rotary voice coil actuators 18th July 2018

- What is a voice coil actuator? 1st May 2018

- High force DC linear actuator ensures a hysteresis free movement 31st January 2018

- The latest open XY positioning system 6th September 2017

Write a comment

No comments