Flexible installation model added to compact servo actuator range

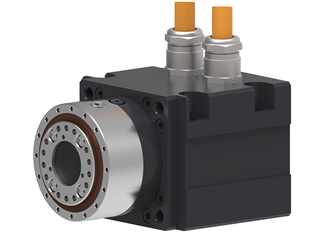

The DriveSpin (DS) range of ultra-compact and high-torque rotary positioning actuators from Spinea integrate an AC servomotor and feedback device with the TwinSpin high-load capacity reduction gear unit. The DS range available from Heason Technology has now been expanded to include a new variant that offers additional mounting possibilities.

The DSM series features a housing design with adaptable fixings for the direct and versatile mechanical interfacing of end effectors and other automation components without the need for adapters or support brackets. Its modular design also allows the simple assembly of self-supporting ‘kinematic’ modules by connecting DSM’s together.

Joining the standard and hollow-shaft variants of the DS range, it provides tilting and torsional stiffness, high precision and accuracy with minimal vibration and long service life. The torque-to-size ratio across the whole range will save space and cost in robotics, precision positioning stages, machine tools and other high performance machine applications,

Spinea’s TwinSpin reduction gear units feature a patented trochoidal gear reduction principle that is based on rotating outer and inner planetary gears supported in precision high load capacity needle roller bearings.

As the input shaft and gear rotates, the eccentric action of the planetary gearing - with almost 50% simultaneous gear meshing - rotates the outer ring in the same direction, efficiently transmitting very high torque with backlash-free performance.

The new DSM model is available in three frame sizes with square sections of 50, 70 and 110mm in compact lengths (just 150mm for the 70mm frame option). An impressive specification includes continuous torque output from 18Nm for the 50mm model and up to 122Nm for the 110mm model - with acceleration and braking torque rated at 200% continuous torque.

Output speeds in the order of 50-80rpm are dependent on gear ratios and bus voltages which range from 24- 560VDC. A big feature is the TwinSpin’s characteristic torsional and tilting stiffness values where the 70mm model boasts 7Nm/arc-min and 35Nm/arc-min respectively and across the range values are equally impressive. With superior hysteresis, excellent backlash and other significant performance related specifications the DSM is equipped for very high performance and high load rotary positioning – with long life and proven reliability even at high throughput rates.

Feedback options include resolvers, single & multi-turn absolute encoders, or HIPERFACE or EnDAT encoders. A brake option is also available - length may vary due to the choice of feedback device and optional brakes.

Alternative position feedback options are available from Heason Technology including external load mounted rotary or linear encoder systems. With its own in-house design and build system integration service, the West Sussex based integrator can supply the DSM series or other Spinea TwinSpin-equipped precision actuator assembles as part of fully automated motion assemblies that include bespoke mechanics, servo drives, feedback sensors and motion controls, with cable management and other automation system components.

Similar articles

More from Heason Technology Ltd

- Decentralised EtherCAT motion system offers machine cost benefits 10th September 2018

- Encoder with high pressure option increases application scope 12th June 2018

- Motion system demo´s from Heason Technologies at MACH 3rd April 2018

- Highlighting washdown motors and motion components 28th March 2018

Write a comment

No comments