Electric drives - easy to select, easy to connect, easy to configure

Warren Harvard, Product Manager for Electric Drives at Festo, discusses the challenges facing machine builders and what can be done to improve the easier selection, connection and configuration of electric drives solutions.

What are the biggest challenges currently facing machine builders?

For special purpose machine builders, being able to specify a solution quickly and easily with total confidence in the performance is key to winning business in an efficient manner. For the replicating machine builder, the challenge is to find a way to build a standard solution that can be re-configured easily and cost effectively to meet customer standards in terms of fieldbus and connectivity protocols. In both cases it’s a highly competitive environment. Cost is critical but it’s often the first to respond with a quote that gains the advantage.

However, there is an inherent conflict between reducing time and reducing cost. Shopping around multiple suppliers can identify lower cost components, but the all-important final price often masks the associated engineering sourcing, procurement, design and compatibility costs. Building a solution using multiple components from different suppliers is actually complex, time consuming and risky.

There is always the potential that a mistake has been made – particularly when trying to ‘marry up’ different manufacturers’ data, which is frequently presented in different formats, units etc. The potential for issues to arise around compatibility and connectivity is high and, with multiple suppliers involved, it is often unclear where ownership of that risk lies.

How does this affect the end users?

Time pressures and a desire to avoid risks can lead to disadvantages for end users. It reduces the opportunities for machine builders to consider all the options and add real value at the design stage. Instead, the tendency is to stay with a proven specification and often to adopt a ‘belt and braces’ approach. This can mean that the recommended solution is not optimised, may be over-engineered to provide a safety factor, and is more expensive than it needs to be.

As a result, the end user can get a less efficient, more complex solution than necessary – creating potential service, maintenance and life time cost issues.

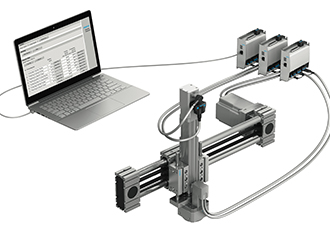

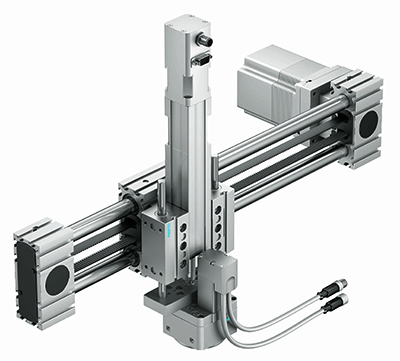

Above: Electric linear gantry YZ with rotary drive

An example

Electrical positioning systems are a good example. They are commonly used in almost any machine that needs to position and move objects. Typically consisting of a positional controller, motor, gearbox and mechanical axis, cables and connections, their overall system performance is a result of the combined performance of the individual components.

Machine builders frequently source these different elements from two, three or more suppliers - introducing questions around performance, compatibility and connectivity. Because of this it is often easier, quicker and safer to stick to previously used solutions, rather than look for new ones.

The effort and risk involved in deviating from a known solution is a real barrier to cost and performance optimisation. As a result, a machine builder may choose to stick to a known servo electric system that provides top end performance even when the application doesn’t require it – and when there are other, more cost effective technologies that can be used. For example, if dynamic movement requirements are not onerous, closed loop stepper motor technology offers the same control capability and can manage similar loads to servo systems, at a lower cost.

What can be done to improve this situation?

Suppliers need to make it easy for machine builders to match components in order to deliver the required performance - easy to select, easy to connect, easy to configure. Manufacturers of electric drive components can play an important role by providing the tools and products to make it easier for designers and machine builders to make the right choices. There needs to be more understanding of designers’ needs by the component manufacturer so that they can provide fast, knowledgeable support through the specification, buying and machine building process.

What can Festo offer?

Festo offers a range of motion solutions, from simple positioning to high end servo electrics. The company’s overall approach is to focus on the needs of the machine builder. Festo’s aim is to make it quick and easy for designers to select the various components and understand their combined performance and overall costs. It does this by supplying all the elements in the control chain that are needed to make the solution work, both mechanical and electrical. Harvard added: “The result is an integrated and joined up solution – easy connectivity, guaranteed system performance and compatibility, plus technical and customer support – all from one source. And because we offer all the elements, machine builders and designers can take advantage of a free simulation tool that provides a range of technical solutions based on the application requirements. The results provide guaranteed performance, known costs and, critically, the opportunity to make fast, optimised risk-free decisions.

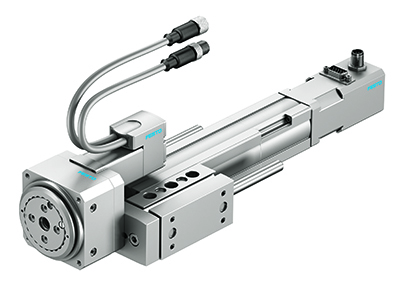

Above: Cylinder-rotary drive combination from the modular system

“A good example of our ability to offer performance oriented solutions is our Optimised Motion Series (OMS). We used our expertise to develop a total package that offers one cost effective solution for many positioning applications. Based on closed loop stepper motor technology, the Optimised Motion Series of electric drives has been developed to provide easy to use, multi-position control at a highly focused price point. So, OEMs and machine builders can order a complete electric drive system using one product code and get all the components they need – including the cables, connectors and gearbox – delivered in one box. Because you are dealing with one supplier for all the components, compatibility is guaranteed.”

What about connectivity?

The OMS Series uses Festo technology to facilitate connection to various end user protocols. Machine builders can therefore design a standard electric drive system that, with a simple inexpensive change to the connectivity node, can communicate directly with a wide range of systems such as:

- I/O-link

- CANopen

- DeviceNet

- EtherCAT

- PROFIBUS

- PROFINET

The programming is supported with simple, modern, web configuration tools. All parameters are downloaded from the Festo web server rather than having to be entered manually, significantly reducing programming time and the potential for error.

The Festo advanced CMMO stepper technology enables lower cost motor technology but with advanced control capability, including force and position control delivered in a smooth and optimised motion profile. Open loop control is the lowest cost option, but where accuracy and continuous monitoring is required then encoder feedback enables the system to operate in a cost effective and full closed loop servo mode.

What about support with specification and commissioning?

Festo has an online software tool called Positioning Drives that is freely available and will help OEMs and machine builders select the optimum electric drive package for their application.

Harvard continued: “You just enter the application details and the software comes up with a range of technically matched solutions. The software’s in-built mechanical knowledge and understanding takes into account the mechanical axis – whether piston rod, rodless gantry, cantilever-based linear drives or guided rotary tables – and provides the optimum product choice in terms of bearings, guidance and application demands such as mass, centre of gravity, off-sets, velocity, etc. Electrical compatibility is assured because once the optimum mechanical drive is selected the motor and gearbox are matched to the performance requirement.”

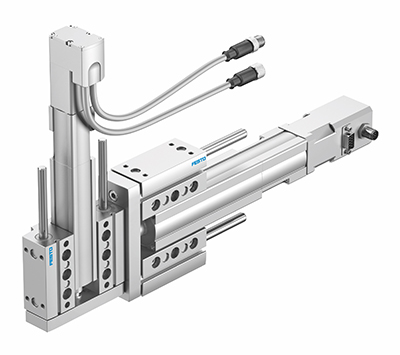

Above: Combination of the electric cylinder EPCO for pick and place tasks

The Positioning Drives software provides information about the safety margins offered by the proposed solutions so the designer can make an informed decision – making electric drive selection quick, simple and risk-free. There is also free access to CAD drawings in all standard native formats, electronic datasheets for easy technical file compilation, performance assurance and a single complete system price, so all the information is available in one place.

Once the machine builder has taken delivery, the chosen OMS package can be assembled out of the box using one tool – an Allen key. Because all the components come from one manufacturer the mechanical interfaces are designed to work together to provide secure, aligned axes - so there is no need for additional, expensive brackets and adaptors. When installation is complete, Festo’s free web configuration tool makes it fast and error-free for the controls or commissioning engineer to set-up and prove the solution.

What are the benefits of using the OMS electric drive package?

- Speed to design, thanks to our free software selection tool

- Modularity in terms of connectivity options to fieldbus systems

- Fast to quote customers with different fieldbus options – no need to redesign whole electric drive system, just change the fieldbus node

- Fast delivery – one week

- Performance guarantee of the system – proven in the software

- Cost effective technology (closed loop stepper appropriate for many applications)

- Simpler process - one supplier, one order, one purchase number, one delivery

Similar articles

More from Festo Ltd

- Secure cloud interface enables manufacturers to start industry 4.0 16th November 2018

- How to maintain network security in Industry 4.0 13th July 2018

- One-day seminar on basics of Industry 4.0 23rd February 2018

- Taking a focus on smarter automation 24th January 2018

Write a comment

No comments