Software technology oriented towards future technologies

Software technology to meet the needs of emerging applications requiring higher levels of data analysis and a greater numbers of access points from Progea has been introduced by P4A. Built from the ground with technologies such as .NET, OPC UA and HTML5, Progea’s Automation Platform.NExT is oriented towards technologies of the immediate future.

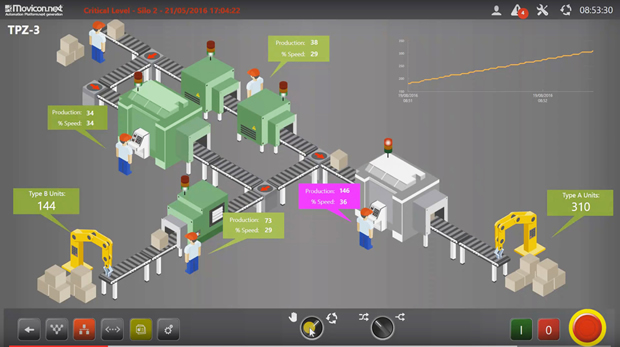

Automation Platform.NExT complements the existing Movicon 11 product by offering a comprehensive and future-proofed solution developed by investing in new and emerging technologies. Applications are identified as supervision projects designed for networked and standalone architectures that involve deploying SCADA based on the latest multi-touch HMIs which support the use of higher quality graphics with 3D technologies.

Written from first principals to provide a completely new generation platform, Automation Platform.NExT supports all OPC UA, including Data Access (DA), Alarms & Conditions (A&C) and Historical Analysis (HA).![]()

A key feature of Automation Platform.NExT is its exceptional, next generation graphics, based on WPF (Windows Presentation Foundation) and XAML (Extensible Application Markup Language). WPF uses a vector graphics-rendering engine that is independent from the resolution and so takes full advantage of the modern graphics and Direct X hardware components.

It offers a complete set of development features, including XAML, controls, data association, lay out, 2D and 3D graphics, animation, styles models, documents, multimedia elements, text and typography. These technologies enable automation software developers to embrace the radical changes in device interaction that are evident in the industrial world, meeting current and emerging user expectations for more interface functionality.

In addition Progea’s newly developed Virtual File System (VFS) technology guarantees independence between the platform projects and collected and archived data so that such data can be stored in a relational database, on a local file (XML) or on the Cloud. The architecture transparently uses the ADO.NET technology to allow the user to freely customise the physical access procedures of the various data providing modules.

The vast amount of data generated by a typical production process is of little use if not properly analysed, and Progea has addressed this with plant intelligence for analysing, measuring, comparing and predicting productive performance. Automation Platform.NExT integrates all of the tools needed to perform these tasks in a simple and efficient way, either locally, over the web or at enterprise level.

An important development is the web server module that enables users to publish reports over the webs via HTML5 technology, where they can be viewed remotely. The HTML5 technology also means local HMI screen interfaces can be deployed on the web, enabling personnel to manage systems without physically having to be on the premises, even using mobile devices if required.

Automation Platform.NExT also recognises the importance of guaranteeing the maximum level of security and reliability. It offers a comprehensive and robust system of managing users and passwords. This ensures that project design engineering is done in conformance with strict security regulations as part of an integral and simple system procedure.

User profiles can be defined with the option for mixed configurations among project users, users defined by administrators in runtime, Windows dominion users, and users from connected Child projects. Access privileges can also be associated to all the command and action functions as well as to each individual project tag.

Paul Hurst, managing director of UK Progea distribution partner Products4Automation (P4A) commented: “Automation Platform.NExT has been four years in the development and represents a complete rethinking of the concepts of automation software. It offers a superior way to create SCADA and HMI applications based on a cutting edge and innovative architecture. It is undeniably a revolutionary architecture based on the most recent innovations in the IT sector, and also delivers on the interoperability and connectivity principles that form the basis of Industry 4.0.”

Similar articles

More from Products4Automation

- Will 5G be a game changer for SCADA? 18th December 2019

- Controlling a textiles factory from home 22nd November 2019

- Increase production flexibility with better batch management 8th October 2019

- Cruise passengers stay cool with HVAC control systems 28th August 2019

technology at Jacobs Vehicle Systems.JPG)

Write a comment

No comments