Simulation tool release addresses complexity challenges

The recently released ANSYS 16.0 offers advanced functionality, from simulating the IoT's software/hardware interactions to better understanding advanced structural materials, enabling engineers to rapidly innovate products. ANSYS 16.0 advances the company’s entire portfolio, including structures, fluids, electronics and systems engineering solutions, allowing engineers to validate complete virtual prototypes.

ANSYS 16.0 delivers capabilities to verify electronics reliability and performance throughout the design process and complex electronics industry supply chains. Also included is the ability to create 3D components and integrate them into larger electronic assemblies, facilitating the creation of wireless communication systems. Simulation-ready 3D components are created and stored in library files that can be added to larger system designs without the need to apply excitations, boundary conditions and material properties.

As part of the release, ANSYS is introducing the ANSYS Electronics Desktop. This single-window integrated interface brings electromagnetic, circuit and systems analysis into a single working environment to maximise productivity.

ANSYS 16.0 accelerates the modelling process for thin materials such as sheet metal and composites, used to reduce weight, and define how parts are connected in a complete assembly.

ANSYS 16.0 also provides solutions for elastomers like rubber, which are often used in seals and vibration dampers. Seals can become severely distorted and come into contact with other parts, which adds to the complexity of the simulation. ANSYS 16.0 features adaptive remeshing, which refines the mesh in highly distorted areas without the need for the user to stop the simulation manually.

Contact simulation between multiple parts has also realised many advancements in ANSYS 16.0. These are some of the most challenging simulations for structural analysis, especially with the expansion beyond traditional engineering material.

“The contact improvements released with ANSYS 16.0 will be very useful to further refine the modeling of stent deployment in cerebral aneurysms,” said Mathieu Sanchez, Co-founder and R&D director, IRRAs Technology. “The combination of better contact management and visualisation and customisation tools available in ANSYS 16.0 should help us to bring engineering simulation benefits to the surgeons.”

ANSYS 16.0 reduces complex fluid dynamics preprocessing time for complex models by up to 40%, and reduces the time for optimising design changes by leveraging the adjoint optimisation technology and making it more practical for engineers to use. The adjoint designer tool enables engineers to perform multi-objective shape optimisation, including constraints. They can now use the adjoint solver to model up to 50 million cells.

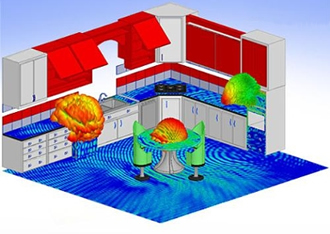

As part of the launch, ANSYS is introducing ANSYS AIM, an immersive unified multiphysics simulation environment that lowers the barrier to entry for multiphysics simulations. AIM’s guided simulation process paradigm delivers high levels of automation and provides opportunities for customisation to automate engineering best practices.

“Global enterprises have already embraced ANSYS as the engineering simulation standard for proven physics, high performance computing solutions and a unified modeling environment,” said Jim Cashman, President and CEO, ANSYS. “ANSYS 16.0 builds on that 45-year legacy by delivering even more functionality. By taking advantage of these capabilities, enterprises can bring their products to market faster by reducing or eliminating their reliance on physical prototypes. And by fully leveraging the capabilities of this release, they can unlock the promise within their products.”

“ANSYS solutions already complement our product development process perfectly, so we’re looking forward to the capabilities offered in ANSYS 16.0,” said Robert Terhune, Mechanical Engineer at 4moms, which develops safe baby gear. “Validating prototypes on the computer using ANSYS simulation software, in addition to physical tests, drives us to higher levels of innovation while getting our products to market faster and more cost-effectively.”

“The IoT is changing the way that nearly every product is created,” said Larry Zu, President, Sarcina Technology. “That creates unique challenges for Sarcina Technology's high performance ASICs and PCBs. The advances in ANSYS 16.0 enable Sarcina to create our products faster and more reliably, helping to connect the components of the IoT quicker than ever.”

Similar articles

More from ANSYS

- Cummins Standardises On Ansys Engineering Simulation Software 17th March 2015

- Simulation shows material behaviour during heat treating 23rd February 2015

- Simulation tool release addresses complexity challenges 28th January 2015

- ANSYS 12.1 Enhancements Support Fast Product Design and Validation 18th December 2009

technology at Jacobs Vehicle Systems.JPG)

Write a comment

No comments