Twiflex Limited

Address:

104 The Green

Twickenham

Middlesex

Tel:

Fax:

Email:

TW2 5AQ

United Kingdom

Twickenham

Middlesex

Tel:

Fax:

Email:

TW2 5AQ

United Kingdom

Twiflex Limited articles

Displaying 1 - 12 of 12

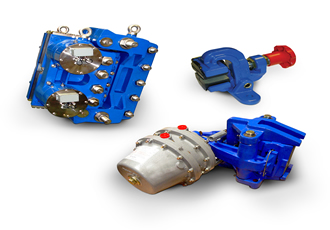

Locking braking system supports propulsion shaft maintenance

Regular maintenance of the propulsion shaft and propeller is required to ensure that all components are operating efficiently and safely during the operational life of a ship or ocean going vessel. Part of the process requires aligning and locking the shaft in place to enable this work to be carried out by the ship’s engineers. Twiflex has launched a Turning, Locking & Braking (TLB) System that provides a compact solution to allow the shaft position to be set and locked when the vessel is stationary.

14th July 2017

New partnership strengthens support in Germany

The end of 2015 brought the announcement that one of Germany’s power transmission brands would be partnering with UK manufacturer, Twiflex, to provide the German market with direct access to a wide range of heavy duty braking systems. Both brands are owned by Altra Industrial Motion, meaning that OEMs, end-users and resellers are all able to benefit from the expertise of two leading manufacturers from a single point of contact.

16th November 2016

Rapid stopping speeds featured in gold mine brakes

As a member of the Altra Industrial Motion Group, Twiflex has provided a parking and emergency brake for use on hoists at a gold mine in Elko County, Nevada. The VCSD-VR brakes are installed on a motor pinion, operating on a 1.168m diameter disc to produce a total torque of 128kNm.

28th September 2016

Twiflex launching new system at SMM

A new TLB (Turning, Locking and Braking) system is being launched by Twiflex at the SMM in Hamburg this September. Part of the Altra Industrial Motion Group, the company will be demonstrating its ability to provide innovative solutions for controlling propeller shafts at sea or during routine maintenance.

17th August 2016

Heavy duty brake specification streamlined by Stieber

The complete range of heavy duty brakes from world brand Twiflex, are now being offered from backstop, brake and clutch specialist, Stieber GmbH, who are part of the Altra Industrial Motion group. Stieber can also provide local application engineering support and package bespoke mounting equipment and ancillary components to meet customers’ exact specifications.

20th July 2016

Crucial braking system for London underground’s escalators

Escalators are a huge contribution in keeping London’s Underground system running smoothly with 430 escalators on the network. Nearly 90 million passengers make more than 1.3 billion journeys every year on the underground, all of which would not be possible without Twiflex’s braking systems for the escalators.

13th July 2016

New VSD brakes harness the latest performance developments from Twiflex

The range of modular brake systems from Twiflex Ltd has been further expanded with the launch of the new VSD series, which incorporates several of Twiflex’s newest technological improvements. Designed for use in a variety of industrial braking applications, the VSD series is simple to install, adjust and maintain.

10th June 2016

Twiflex continues brake range expansion for optimised performance across all applications

Specifying a brake which will operate reliably and efficiently, with minimal maintenance intervention, is a challenge that must balance initial expenditure with the through-life costs. The main factors to consider include more than simply the duty (whether the brake is being used for dynamic stopping, static holding or continuous tensioning), but also what sort of environment the brake will be located in; whether there are particular space constraints; the operating medium; and if access for periodic maintenance will be possible or not.

18th December 2015

Getting the most from heavy duty brakes

Heavy duty braking system designs are as diverse as the different industries in which they are employed. From marine and mining to metal working and paper processing, systems are required to perform static, dynamic and emergency braking with precise controlled force. Quality is of the upmost importance in these products as the cost of a short service life can often be extremely high for the end-user. However, as with all things mechanical, it is possible to improve the reliability and life span of all braking designs with good specification, correct installation and correct maintenance procedures.

13th August 2015

Twiflex Disc Brakes Meet the needs of Overland Coal Conveyors

When coal processing plants are an appreciable distance from the mine, how best to transport the coal from one to the other is a key consideration. It is not unusual for the processing plant to be tens of miles away, which might at first glance suggest delivery by truck. But overland conveyors can often provide a far more economical solution, providing cost reductions in the order of 20-40% or more.

4th May 2012

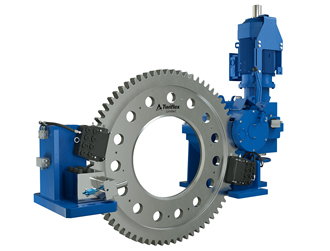

TWIFLEX MODULAR BRAKING SYSTEM ENSURES SAFETY AND RELIABILITY ON SAG MILL AT NEW COPPER AND GOLD MINE

When Mount Milligan Mine in British Columbia, Canada, commences production in 2013, it is anticipated that it will produce 81 million pounds of copper and 194,000 ounces of gold annually – vital at a time when demand for copper in particular is at an all time high and likely to outstrip supply for years to come

4th August 2011

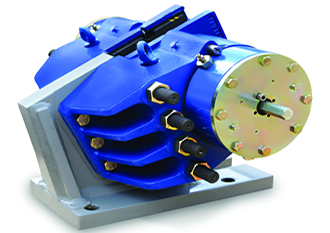

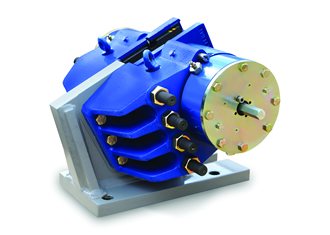

New Twiflex VCS MK 4 Caliper Brakes engineered with 50% more pad area for improved performance in demanding applications

Twiflex Limited’s new technologically advanced VCS MK 4 caliper brakes have been engineered to provide a 50% increase in pad area, providing improved stopping and holding in a wide range of critical applications, including mine hoists, conveyor drives, cranes, ship loaders, wind turbines, and drill rigs in industries including mining, steel, pulp and paper, and marine.

24th May 2010

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex