BEKO TECHNOLOGIES Ltd

Address:

2 West Court

Buntsford Park Road

Bromsgrove

Worcestershire

B60 3 DX

United Kingdom

Buntsford Park Road

Bromsgrove

Worcestershire

B60 3 DX

United Kingdom

Phone: +44 / (0) 1527 / 57 57 78

Fax: +44 / (0) 1527 / 57 57 79

BEKO TECHNOLOGIES Ltd articles

Displaying 1 - 19 of 19

High quality water chillers for any application

BEKO TECHNOLOGIES UK has introduced a range of industrial chillers. These chillers are suitable for a variety of applications and industries such as laser cutting and machine tools, food and drink, automotive, medical, oil and gas, plastic moulding, agriculture and air conditioning. The CWT chiller range was specifically designed to meet the application requirements of industry by offering precise control of refrigerated water temperature while operating over long time periods with varying load demands.

17th July 2018

Why is calibration of your instruments so important?

According to BEKO TECHNOLOGIES, calibration of your instruments is very important. The main reasons for this are to ensure the reliability of the instrument, that it can be trusted and to determine the accuracy of the instrument and to ensure the readings are consistent with other measurements. Considering the costs arising from legal action for damages that might be filed against you, the expenses for proper calibration and adjustment are minor in comparison.

16th May 2017

Measuring technology range extended on flow meter

The METPOINT FLM flow meter from BEKO Technologies measures the compressed air volume flow, which is the basis for accurate consumption analyses for cost reduction and effective energy management. METPOINT FLM sensors reliably detect leakage, overloads and malfunctions. Based on the analysis of the sensor data, the components of the compressed air system can be adjusted for optimum efficiency.

8th May 2017

DRYPOINT AC new generation

BEKO TECHNOLOGIES will launch this month the latest generation of the DRYPOINT AC compressed air adsorption dryers. These models come in 10 different sizes for volumetric flow rates from 100 to 1000 m³/h and operating pressures from 4 to 16 bar (gauge). The cold-regenerated adsorption dryers extract moisture from the compressed air to a pressure dew point of -40° C.

16th May 2016

Beko Technologies Exhibit at AIR-TECH 2016

Beko Technologies will be exhibiting at the Air-Tech show 2016 at the NEC, Birmingham from 12-14th April. Please come and see us in hall 3A at stand AF244.

18th January 2016

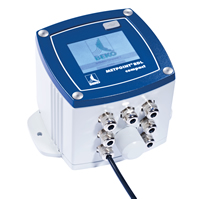

Continuously monitoring medical compressed air

With a system that was specifically developed for monitoring the compressed-air quality in the medical field, the compressed-air system company BEKO TECHNOLOGIES extends its METPOINT measuring equipment family. The new device for the continuous quality assurance of breathing air monitoring boasts decisive unique features, such as a daily auto calibration and measuring-gas humidification for the increased operational reliability and long-term stability of the measuring cells.

4th June 2015

Refrigeration dryer with a plus in efficiency

Full flexibility between the smallest delivered quantities and the peak load – with this, the new refrigeration dryers of the DRYPOINT RA eco series from BEKO TECHNOLOGIES achieve decisive efficiency gains as regards the energy consumption. With fluctuating compressed-air removal or changed ambient conditions, the energy consumption can now optimally be adjusted to the demand. Compared to conventional refrigeration dryers, which are generally designed to meet the maximum requirements, which has the potential to save up to 80% of the operating costs in the partial-load range. Simultaneously, the condensate that develops during the compressed-air drying is discharged without compressed-air losses by means of the integrated BEKOMAT - another gain in efficiency. In this manner, DRYPOINT RA eco achieves optimum results at a fluctuating volume flow under a reduced input of resources. This eases the financial and environmental burden in equal measure because the largest savings derive from the energy that we do not use.

23rd April 2015

A Mobile Logger For Sustainable Analyses

Beko Technologies have extended the METPOINT BDL graphic-display recorders series with a mobile variant for data logging in compressed-air and compressed-gas applications. The new METPOINT BDL portable will complete the stationary standard and compact versions of the successful measurement equipment series.

23rd April 2015

Compact data logger highlights savings potential

BEKO Technologies has spawned a little brother to its METPOINT BDL data logger. The METPOINT BDL compact data logger allows for the connection of 2 - 4 transducers or sensors in a user-defined manner with pressure transducers, for example, or with pressure dew point transmitters, volume-flow sensors, temperature sensors, clip-on ammeters, etc.

28th January 2015

New 5 year extended warranty on refrigeration dryers from Beko Technologies

BEKO TECHNOLOGIES are pleased to announce that from 1st January 2015 we are offering an extended 5 year warranty as standard with the DRYPOINT RA refrigeration dryers. In addition to this we will not be increasing our prices on the dryers this year.

15th January 2015

Medical gas quality monitor calibrates itself

With a system specifically developed for medical in-field compressed air quality monitoring, BEKO Technologies extends its METPOINT measuring range. The device for the quality assurance of medical gases boasts unique features, such as permanent auto calibration and special technology for increased operational reliability and long-term stability of the measuring cells.

22nd December 2014

Sensors capture compressed air measurements

BEKO TECHNOLOGIES has developed the METPOINT sensor technology to continuously record all the relevant parameters at the critical control points of compressed air. It supplies the means to implement energy management, for example in accordance with ISO 50001, or to meet the demanding HACCP or GMP requirements.

12th October 2014

Catalyst system achieves oil-free compressed air

BEKO TECHNOLOGIES has announced the introduction of a catalyst system delivering a constant supply of oil-free compressed air with a barely detectable maximum residual oil content of 0.001mg/m3. Meeting the stringent oil content stipulations of ISO 8573-1, class 1, the BEKOKAT devices break down technical and economic barriers that are usually imposed on conventional compressed air treatment.

9th September 2014

Test quality of compressed air with BEKO TECHNOLOGIES

BEKO TECHNOLOGIES service department can offer air quality tests to enable customers to know what the quality of the compressed air is that they are using. This can be in bodyshops, food packaging companies, automotive, pharmaceutical industry and many more. From this BEKO TECHNOLOGIES can advise what, if necessary, the customer requires in the way of air treatment and filtration.

20th June 2014

METPOINT OCV - Oil vapour in compressed air – Safety via 24/7 process reliability

Even oil-free components and compressors are no guarantor for oil-free compressed air due to impurities in the ambient air / intake air. In most cases, a certain residual oil content cannot be entirely avoided.

19th October 2009

Food-grade compressed air for the sweet side of life

Optimisation of the production processes in the Alfred Ritter GmbH & Co.KG required an improvement in compressed air quality. The problem was clearly defined: Compressed air for the pneumatic handling of cereals, cocoa powder and other primary matters in the production of chocolate had to be in accordance with the strict requirements of the HACCP concept. This concept is a preventive system which ensures the safety of food for consumers. Developed in 1959 in the USA for NASA. Under German law, HACCP became a constituent part of the Food Hygiene Ordinance in 1998. In the EU, it came into effect in 2006, together with the new hygiene regulations package.

19th October 2009

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex

resized.jpg)

.jpg)