Range of die sink machines offers unbeatable EDM productivity

EDM machine tool manufacturer, ONA has launched its new range of ONA QX range of die sink machines. As the principal new product for 2016, these machines increase productivity, surface quality and EDM machining precision to hitherto unseen levels.

Developed and manufactured at ONA’s facilities in Spain, the QX range of machines include a new 100% digital generator that provides great benefits to users of this technology. Especially significant is the increase in productivity in finishing operations where an average 60% improvement is achieved both with copper and graphite electrodes, as well as major improvement in the homogeneity of the roughness on large surfaces.

In the mould sector, where the machining of deep and narrow grooves with very difficult cleaning conditions is common, there has been an increase in productivity of up to 50% for this type of work, without any increase in electrode wear.

The increase in productivity of QX machines is linked to a significant reduction in electrode wear, which can last up to five times longer depending on the type of application. This advantage allows significant cost savings and simplifies the performance of many jobs where previously it was necessary to use two electrodes now one is often sufficient. This significant reduction in electrode wear enables QX machines to create cavities with a high aspect ratio, as well as to substantially improve the precision in micro-cavities, ensuring the generation of up to five micron in the inner radius of corners, compared to the 15 micron of previous machine designs.

New all-digital generator offers unprecedented flexibility to adapt the technology to the special and specific applications of each customer. The generator has been developed with the specific requirements for quality demanded by customers in the aerospace sector, in which advanced materials of exceptional hardness, such as nickel- and titanium-based alloys, are used. An equivalent to a lapped finish, a surface roughness of just 0.08µmRa can be achieved by the new generator.

Another advantage of the levels of control offered by the digital generator is the application of EDM micro-machining, used when the surface area is less than 10mm2. Typically used to create mould tools for the connectors used in every electronic device, such as mobile phones, audio visual systems and automotive applications in the consumer market to high tech industry sectors such as aerospace and satellite communications.

The EDM process plays a significant role in the manufacture of the mould tools for these demanding components. EDM micro-machining operations have gaps of less than 0.05mm, corner radii below 10micron and achieve a surface finish of 0.1-0.25µmRa. A vital part of successful micro-machining is the control and resolution of the charge intensity.

At low intensities, of less than 4A, if the intensity is dependent on the input voltage and discharges it becomes very difficult to ensure that the programmed current is achieved at the electrode. The digital QX generator has intensity scaling of 0.1A that allows each discharge to be finely controlled to meet the programmed parameters.

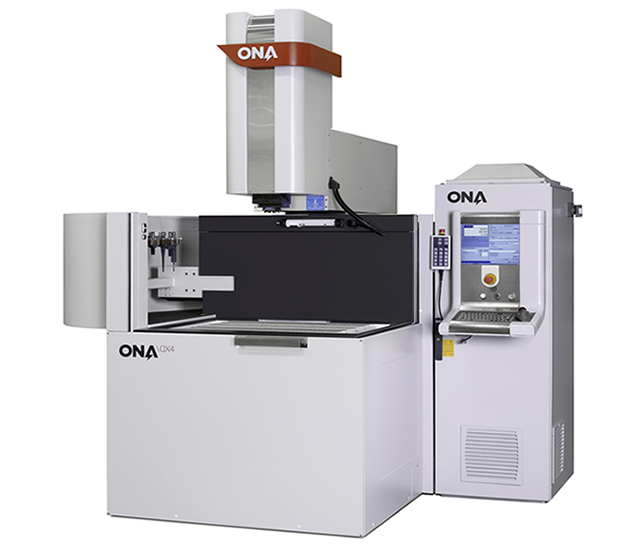

The new family of ONA QX die sinking EDM machines was officially launched at the recent BIEMH exhibition, held in Bilbao, Spain during June 2016. The ONA QX4 model that features travels of 600x400x400mm in X, Y and Z, as well as the large model QX8 Modular were demonstrated on the company’s stand. QX Modular machines have a modular and versatile design that allows each customer to configure the machine to their exact specification, choosing from 40 different standard configurations.

The largest model in the QX Modular series is the QX10 machine, which features axis travels of 3000x1500x1000mm in X, Y and Z respectively and permits the loading of work pieces up to 25 tonnes. The smallest model, the QX7 machine, has axis travels of 1500mm in X, 750mm in Y and 650mm in Z and accepts loads of up to 15 tonnes on the worktable. All machines in the series can also be fitted with two heads controlled by separate CNCs, making it possible to independently machine two cavities at the same time on a large work piece.

Finally, the ONA QX range of machines features a powerful CNC that can control up to eight axes simultaneously. The controller also offers an open architecture, aligned with Industry 4.0, enabling full integration of the machine into any existing or planned enterprise management and control environment.

.jpg)

Write a comment

No comments