High speed doors hold key to dust control in food operations

A breach of hygiene standards could cause a professional food processing manufacturing, distribution and handling operation to be shut down – possibly for good. High speed automated doors can help secure working areas, as Alan Ryder of Sara LBS explains.

Environmental control is critical for organisations dealing with food, particularly food for human consumption. One of the key elements to doing this is securing the workplace from external influences, whether from the outside or from other departments where hygiene is not such a critical issue. However some form of entrance/exit is always going to be required, and for this a high speed automated door is probably the best solution as it will minimise the time the door is open, always shut promptly and requires no physical contact which could facilitate bacterial transfer.

So, what hygiene threats does an automated door system protect against?

The threat to hygiene most people think of is probably bacteria. There is something of a general perception that most bacteria are airborne and can be blown in through an open door. However, this is not quite right: only a few bacteria travel through the air, most are transferred from object to object, often via people’s hands. Thus, a door will stop airborne bacteria, but unless it is automatic, the handles or operating button may provide a route by which bacteria can be transferred and carried into the workplace.

For maximum hygiene protection, all surfaces of a door, its frame and related parts should be of a material that does not encourage bacterial activity, such as stainless steel, be designed for easy wipe down (including internal surfaces), not have nooks and crannies where bacteria can thrive, be open at the bottom so that water and cleaning fluids can run off rather than pooling and becoming a dust and dirt trap.

In fact dust and dirt are probably more of an immediate hygiene threat than bacteria. For one thing, they are visible - especially to a hygiene inspector! Dust can easily become airborne, blown around and settle where it is not welcome. Obviously settling on food products will compromise production so is completely unacceptable, while settling anywhere within the production space may encourage bacterial growth, may be transferred to people’s hands or to food products.

A fast opening and closing door reduces the time dust has to enter, while an automatic one that operates without having person after person touch the same handle or button will reduce the sort of relay transfer by which dust and other small particulates travel.

Another consideration when it comes to hygiene is vermin, including insects, spiders, birds, small animals such as mice, and even larger wild animals such as rabbits, squirrels or stray domestic animals like cats and dogs. All of these animals will be naturally attracted towards food aromas, warmth, and in the case of domestic strays to human contact. A fast acting door will go a long way to thwarting their entry into the food handling areas. It should also be noted, that vermin do not only come in from the outside; they could easily transfer from an adjacent area of the building where hygiene practises are not so rigorous, such as an engineering workshop, office or corridor.

Therefore we can add to the design specification of food safe doors that they need to be vermin proof. They should not include materials of construction that cannot be gnawed through by mice or eaten away by insects. Also the physical design should not include any gaps or holes through which animals or insects can pass, nor any crevices or cavities that could provide a nesting site.

The final area in which automatic doors can play a role in hygiene management is temperature control. It is almost inevitable that the temperature on one side of a door will be at least slightly different to that on the other side. So each time the door is opened there will be a temperature gradient and heat will flow freely to the cooler side until the door is closed again, upsetting the optimised temperature in the food handling area. Clearly a fast operating door will reduce this effect.

Food production, storage and distribution are usually temperature-critical activities, so the affects of doors opening and closing has to be considered and managed within acceptable tolerances. However, in a busy commercial environment, there may be a need for considerable traffic in and out of the production area, be it pedestrians, vehicles, or carts and trolleys used in materials handling. Thus doors may need to open multiple times an hour. Again a fast opening and closing will offer advantages by reducing the time that heat has to transfer.

While considering temperature, it should be noted that considerable energy is required to change a work space’s temperature from ambient, either up or down, so that it is optimised for food operations. Fast doors can therefore have a significant impact on controlling energy bills as well as hygiene control.

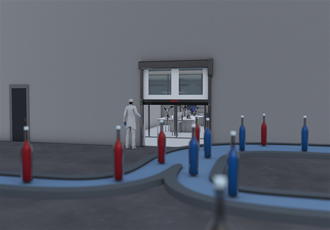

To meet the specific requirements for hygiene and temperature stability in the food industry, sara LBS has developed the Rapid Food Door, with the objective of setting new standards for hygiene, efficiency and user safety, while providing rapid opening and closing. The entire door, side frames, top roll and motor cover, and the bottom profile are made of stainless steel. Smooth surfaces ensure there is nowhere for dust, dirt and debris to accumulate. The side frames are hinged to enable thorough cleaning and disinfecting of internal areas, and are also free-draining.

The door is of clear PVC with vertical reinforcement stripes and is powered by a geared brake motor which can be fitted with a stainless steel cover. For maximum safety and superb controllability the motor is controlled by a frequency converter, an electrical safety contact edge and a door line photocell. A graphics screen and simple user interface allow easy set up and automatic operation.

The Rapid Food Door meets all the requirements for access in food processing environments and all European safety requirements for power operated doors.

Similar articles

More from Sara Loading Bay Specialists Ltd

- Fast tracking loading bay fit-outs 10th May 2019

- Keeping your cool when the heat is on 12th February 2019

- Insulated roller shutter doors with improved performance 29th January 2019

- High speed doors keep winter at bay 13th November 2018

.jpg)

Write a comment

No comments