Experience supports turnkey sludge thickeners

Bringing decades of experience to designing, manufacturing and installing sludge thickeners, A&J Fabtech and its units can be used in both clean and dirty water applications. This meets the WRC recommendations and guidelines TT016 (TR189) for potable water. Sludge thickeners work by concentrating impurities into solid form and then separating these solids from the bulk liquid.

The concentration of solids, known as sludge, can contain an almost infinite range of substances and materials - thickening allows them to be collected and disposed of properly.

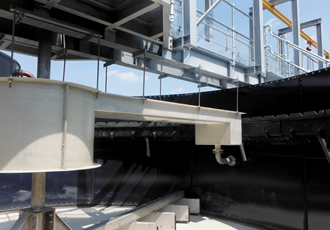

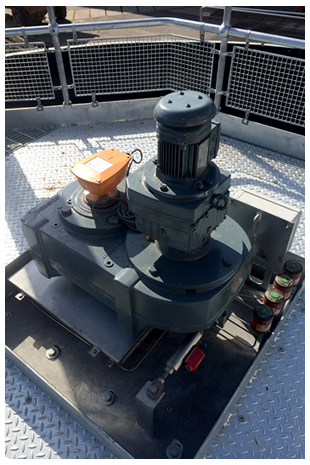

The design concept of A&J Fabtech thickeners is based on a central motor and drive unit attached to a rotating shaft that carries sludge collection scraper blades. These are designed and engineered to collect the thickened sludge at the base and move it to a central hopper outlet, from where it is collected for subsequent processing.

A&J Fabtech has been involved in many projects over the years and built thickeners in sizes from 1.6-20.0m, each one designed to meet the specific needs of the job in hand. The company can provide packaged plants in the form of tank and thickener, in which case fabrication can be in a variety of materials such as painted or galvanised mild steel, duplex grade stainless steel or glass coated materials.

Past projects have seen A&J Fabtech thickeners installed at potable water treatment plants, wastewater works and also in industrial plants where the process conditions can be unique and challenging.

The thickeners are designed to give the best possible concentration of solids into sludge. This reduces sludge volume, which means less need for dewatering and reduced overall sludge disposal costs. Optional features can include inlet diffusers, scum control and sludge blanket monitoring. For process-critical applications, real-time sludge loading monitoring and feedback systems can also be provided.

A&J Fabtech offers a full turnkey solution that can include the design and manufacture of the process tank, thickener mechanism, access stairways and platforms. Off-site pre-wiring and pre-assembly is a popular option, while commissioning by its team of site engineers ensures straightforward and rapid installation.

Similar articles

More from A&J Fabtech Ltd.

- Designs in one week with automated design tool FACT 9th July 2018

- Blending into the background while controlling odour 16th March 2018

- Bigger scoreboard steel structures for Hampden Park stadium 28th February 2018

- Duke of Edinburgh Scheme award given to A&J Fabtech 18th January 2018

.jpg)

Write a comment

No comments