Generator repair keeps the lights on in Darwin

The power station in Darwin started life as a 200MW gas fired installation with three gas turbine generators that started full production in 1987. Having provided the population of Darwin with electricity for 25 years, it was important to ensure the generators continued to provide reliable service. This led to the owners calling on the services of Sulzer to carry out an overhaul of the generator including a rewind of the stator.

The 42kVA generator, operating at 11.5kV, was originally built in 1986, but after more than 25 years in service, the time had come for an overhaul. Using the OEM drawings, combined with the latest CAD, the engineers at Sulzer were able to start on the initial design stages and plan the logistics that would allow the contract to be completed on time.

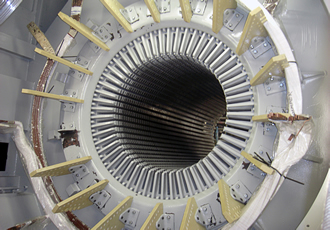

Once the project was underway, two teams of Sulzer engineers, on opposite sides of the world, set about the wide range of tasks required to complete the refurbishment. The service engineers on site in Darwin began with dismantling the generator, while in Birmingham, UK, the coil shop worked on the design of the new high voltage bars and the dummy stator that would be used to check the dimensions of every one of the 108 bars as well as the support blocks for the windings.

Generators can be installed with a variety of coil designs, including 'frog-leg' coils and diamond coils but larger machines more commonly have bar wound stators, mainly because of the sheer size of a finished coil makes handling difficult. Once the bars have been installed the coils are formed by connecting the relevant bar ends together, brazing and then taping.

Throughout the manufacturing process quality control is essential; starting with the controls over raw material quality to measuring every coil for dimensional accuracy to the final electrical tests. Every process is checked against the original drawings and specifications to ensure that the finished product can be easily assembled and produce efficient and reliable service for many years to come.

For Sulzer, the production process for the new bars starts with the raw copper, which is processed using its own in-house facilities to draw and anneal the base copper. The copper strip is manufactured to exacting tolerances before being coated with the first layer of insulation and cut to length.

Each strip is then layered together with many others to make up the basic bar construction, but, its position within the bar must be transposed by 360° in order to reduce eddy current losses. This is a crucial design characteristic and is more commonly known as the Roebel transposition, which would be required in the bar design for this generator.

Once the strips have been properly arranged, a resin tape is applied and they are consolidated in a heated, hydraulic press which ensures the alignment of the conductors within the slots; this is crucial for delivering the maximum efficiency of the refurbished generator.

Meanwhile, in Darwin, the generator was being dismantled and showing signs of its age with some considerable oil contamination of the stator windings being discovered. Having recorded all of the necessary measurements, the old coils were removed and the stator thoroughly cleaned before the core was flux tested.

The flux test is used to measure the condition of the stator core insulation and thus detect any local insulation damage, which can cause the formation of larger eddy currents and local hot spots. Once complete and with a clean bill of health, the stator could be repainted and the rebuild process got under way.

This generator design consists of 54 bottom bars and 54 top bars, all of which have to be manufactured to tight tolerances in order to ensure they fit exactly into the stator slot. Each bar has to be formed and shaped by hand, using the CAD-designed, wooden formers that allow every bar to be produced with exactly the right shape and dimensions. The final shape is then checked again in the wooden dummy stator that was constructed earlier.

Every bar is tested in the dedicated test cell with the results recorded and kept in the engineering archives. Testing includes tan δ, which relates to the power factor of the bars as well as strand-to-strand short circuit testing and the outer corona protection (OCP) surface resistance measurement.

Mike Stanley, General Manager of Sulzer’s Birmingham Service Centre, explains: "Improved production techniques and insulation technologies allow modern coils to improve the efficiency and reliability of existing equipment. Throughout the manufacturing process quality control is essential to maintain production of high quality, uniform coils.

"Starting with the controls over raw material quality to measuring every coil for dimensional accuracy to the final electrical tests, every process is checked against the original drawings and specifications to ensure that the finished product can be easily assembled and deliver reliable and efficient service for many years to come."

At this point the logistics team at Birmingham take over, having already constructed the shipping crates for the bars. Carefully packaging the bars to ensure they arrive undamaged is crucial to ensuring a trouble-free installation in Darwin. The shipment is timed to coincide with the disassembly of the stator on site, so as to avoid any unnecessary delays.

Once all 108 bars have been installed and secured to the end winding brackets, with wedges in place, each bar is subjected to a final high voltage test to be certain that none of the insulation has been damaged during the installation process. With the test results recorded in the project file, the next step is to braze the bar end windings together in order to create the final coils, before taping, sealing and applying the class "H" top glass tape.

With the stator nearly complete, the high voltage terminals were cleaned and tested at 25kV to prove their insulation resistance before they, too, were installed. Having completed the checks and minor work to the rotor, the generator was reassembled and returned to service, ready for another 25 years.

Mike Stanley concludes: "Our engineers are frequently involved in the development of new technical standards as well as new materials technologies, allowing us to develop new designs in line with the latest standards to provide our customers with improved efficiency and reliability. We work with a wide range of clients from small, local rewind shops to large end users and global OEMs and for each one we are able to tailor the level of engineering and technical support to ensure that every job, however big or small, will be completed on time and to the highest quality."

Similar articles

More from Sulzer Ltd

- Construction of Sulzer’s new Birmingham Service Centre on track 8th September 2020

- Electrical distribution powered up for holiday period 1st July 2020

- Rapid reverse engineering 18th December 2019

- The future of the oil and gas sector is now 25th October 2019

Write a comment

No comments